Grizzly 0694 Lathe review and new project

For starters, here is my review of my new lathe. In a nutshell, I really like it. That’s not to say it doesn’t have it’s issues. I have a few criticisms but all in all, I am very happy with it. I have been using it for several weeks mostly for bowls and it is very smooth running, good speed control and very quiet. I had read on another review about it making a whining noise but I did not find this to be true. The electronics work flawlessly. My first issue is with the off switch. It is one of those that when you hit the button, you have to twist it to re-set it. This is not a real problem, but I would like a simple push button like the on button. My second issue is hard to describe but I will give it my best shot. On the shaft there is a sort of collar that is attached with four set screws. The collar expands over the shaft to cover either the hand wheel, the face plate or the chuck installed and holds it in place with four set screws. Here is a shot of it. The set screw on the left is holding the hand wheel on. Kind of a belt and suspenders approach. Probably there to keep the lawyers happy. My problem came when I put a four jaw chuck on. The chuck is removed by inserting a shaft into a hole on the threaded insert for leverage and using it to remove the chuck. With the collar in place, it covers the hole for the shaft. Not a problem you say? You can remove the chuck by using the wrench used to tighten it. True, but if you happen to loosen the chuck from the threaded insert and the insert stays on the shaft, you have to destroy the insert to get it off. I brought this up to the engineers at Grizzly and they admitted they never thought of this potential problem. You can’t operate the machine without the collar as it also covers the bearings. Without it, the bearings would get dirty and fail. My solution was to turn the collar down to get rid of the part that covers the shaft. Grizzly offered to do this and send me the modified one which they did and it works great. Here is a shot of it.

The set screw on the left is holding the hand wheel on. Kind of a belt and suspenders approach. Probably there to keep the lawyers happy. My problem came when I put a four jaw chuck on. The chuck is removed by inserting a shaft into a hole on the threaded insert for leverage and using it to remove the chuck. With the collar in place, it covers the hole for the shaft. Not a problem you say? You can remove the chuck by using the wrench used to tighten it. True, but if you happen to loosen the chuck from the threaded insert and the insert stays on the shaft, you have to destroy the insert to get it off. I brought this up to the engineers at Grizzly and they admitted they never thought of this potential problem. You can’t operate the machine without the collar as it also covers the bearings. Without it, the bearings would get dirty and fail. My solution was to turn the collar down to get rid of the part that covers the shaft. Grizzly offered to do this and send me the modified one which they did and it works great. Here is a shot of it. Yo can see it no longer covers the shaft but it still protects the bearings under it. Problem solved. I hope the Grizzly people fix this on future versions of this lathe. I can’t compare this to a Powermatic or some other big ticket lathe because I have never used them, but I can’t see them being enough of a machine to justify double the price. This is a very nice machine.

Yo can see it no longer covers the shaft but it still protects the bearings under it. Problem solved. I hope the Grizzly people fix this on future versions of this lathe. I can’t compare this to a Powermatic or some other big ticket lathe because I have never used them, but I can’t see them being enough of a machine to justify double the price. This is a very nice machine.

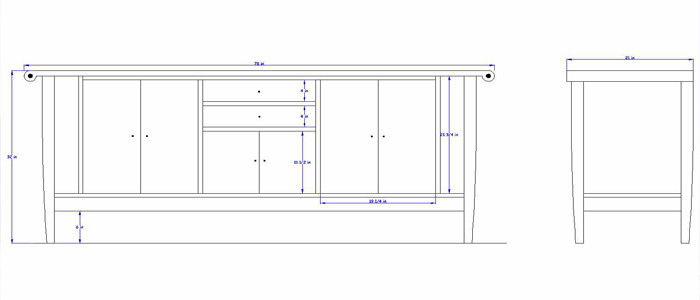

Now, on to my new project. I have to say right here that I have done a couple of project that I have not written about. I will be keeping you all posted about this one. I have a customer that bought a table like these a few years ago. They approached me last fall and wanted a console table to go with it. After a lot of back and forth and brainstorming, we came up with this design.

They approached me last fall and wanted a console table to go with it. After a lot of back and forth and brainstorming, we came up with this design. It’s kind of ambitious but I think it will work fine. The center doors and drawer fronts will be bird’s-eye maple and the rest of it will be red birch. I got the lumber last week and was able to get some nice stuff. The cabinet part will be red birch veneer. This will not only keep the weight down but it should eliminate any cross grain issues and allow me to make a more solid piece. The design is such that the cabinet is structural to the table and using veneer will allow me to make it more solid. I am going to get started by gluing up the leg blanks tomorrow. I need to use glue ups because I wanted the legs about 2 1/4″ square and red birch doesn’t come that big.

It’s kind of ambitious but I think it will work fine. The center doors and drawer fronts will be bird’s-eye maple and the rest of it will be red birch. I got the lumber last week and was able to get some nice stuff. The cabinet part will be red birch veneer. This will not only keep the weight down but it should eliminate any cross grain issues and allow me to make a more solid piece. The design is such that the cabinet is structural to the table and using veneer will allow me to make it more solid. I am going to get started by gluing up the leg blanks tomorrow. I need to use glue ups because I wanted the legs about 2 1/4″ square and red birch doesn’t come that big.

Ok, That’s all for now. I’m sick of typing. I promise to keep you all updated on progress.